By closely checking the process, prospective issues is usually addressed proactively, minimizing the risk of product or service non-conformities and ensuring regular products excellent.

Within a guideline, validation is act of demonstrating and documenting that any course of action, process, and exercise will persistently bring about the anticipated success. It consists of the qualification of programs and equipment. The intention from the validation is in order that high-quality is constructed to the procedure at each stage, and not only analyzed for at the end, as such validation activities will typically include instruction on manufacturing substance and operating methods, instruction of people associated and checking from the technique while in production.

Validation is considered the most acknowledged and significant parameter of GMPs. This post deliver introduction about the process validation of pharmaceutical manufacturing process and its significance according to The U.S. Meals and Drug Administration (FDA). This work should be to present an introduction and typical overview on process validation of pharmaceutical manufacturing process. Quality can't be ensured by sampling, tests, launch of resources and products and solutions.

Process validation will be the documented evidence that a manufacturing process constantly provides an item Conference its predetermined specs and good quality attributes.

Process validation is a complex and multifaceted process that needs mindful setting up and execution. It encompasses different pursuits, including process design, process qualification, and continued process verification.

Process validation is actually a vital Section of high quality assurance inside the manufacturing field. It includes the gathering and analysis of information to make certain that a process regularly produces items that fulfill predetermined specs and good quality needs.

Ongoing process monitoring is also a critical requirement outlined by the EMA. This involves the standard monitoring and Assessment of process information to ensure that the process stays inside of a point out of Handle.

Process Adjustments: Modifications in the manufacturing more info process, such as mixing moments and drying temperatures.

PQ is the final action within the process qualification phase and involves verifying the process regularly produces solutions conforming for their predetermined specs.

Process validation provides a multitude of Rewards which will significantly increase your organization functions and product results. Right here’s how it may make a variation:

Process validation also contributes to ongoing improvement initiatives inside of a corporation. By analyzing process details and identifying areas for enhancement, businesses can greatly enhance their manufacturing processes, resulting in increased performance, lessened waste, and improved overall effectiveness.

Standardize procedures: Acquiring and adhering to standardized treatments assures consistency throughout all validation routines. By creating in-depth protocols, you limit variability and be certain that every single group member follows exactly the same steps.

Among the list of essential elements highlighted within the FDA guidelines is the necessity for a robust validation learn program. This strategy serves like a roadmap to the validation pursuits and makes certain that all necessary ways are taken to validate the process.

Any deviations or traits that may most likely influence product quality have to be discovered and validation of manufacturing process addressed promptly.

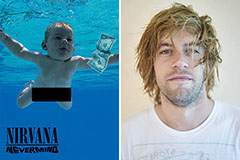

Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now!